Bhagat Cranes provide spare parts of all types EOT Cranes, Hoists and Rail Transfer Carts. EOT cranes and Wire Rope hoists have many consumable parts over time. Its necessary to replace running parts like wheel, brakes, gears, gear lubrication, shafts, rope etc. after certain periods. Its increase performance, safety, reliability and power consumption. Bhagat Cranes provides original quality parts for cranes which may manufactured by any manufacturer.

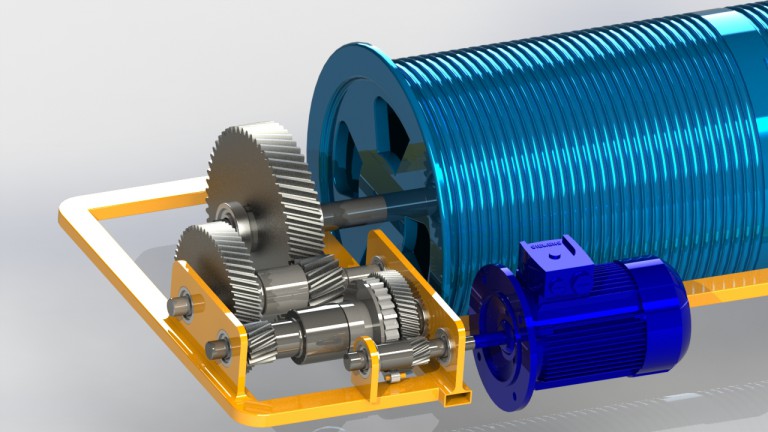

Crane Gear Box

EOT Cranes and Electric Wire Rope Hoists has gear boxes for speed reduction. Crane Duty Gear Boxes are involute’s latest foray specifically designed for crane duty applications in accordance with IS:3177 standards.

Hoist Gearboxes – Two, Three and Four Stage gearboxes are supplied from Crane Hoisting application. The gearbox casing is made from MS fabricated plates. The casing is thermally stress relieved after welding. The casing is accurately machined on horizontal boring machine. The helical gears and pinions are made from rolled/ forged steel of EN9/ EN19/ Cast Steel material as per design requirement. Gears and pinions are oil quenched and tempered to achieve toughness as well as surface harness. Gear teen are machined hob cut. Case hardened gear teeth are supplied as required. Shafts are supported on anti-friction ball and roller bearings. Oil seal seat on shaft are have ground finish. Gears and pinions are Splash lubricated.

CT & LT Gearbox – Two and Three Stage Gearboxes are supplied for Crane CT and LT motion. The construction of CT gearbox is similar to hoist gearbox except that these are provided with inverted T split in housing. The Output shaft can project on both side if so required. For Three stage vertical gearbox forced lubrication arrangement is provided through pump and hoses. Other gearboxes are splash lubricated.

Wheels and Wheel Assembly

Wheels are supported in L type bearing blocks. Wheels are made from forged steel/ cast steel and machined accurately. Wheels are suitably heat treated to achieve hardness of 250 – 300 BHN with volume hardening or 450 – 500 BHN with Induction hardening as per customer requirement. Tram wheels with either non ferrous bush bearing or anti-friction bearing and open gear attached are also supplied as required by customer.

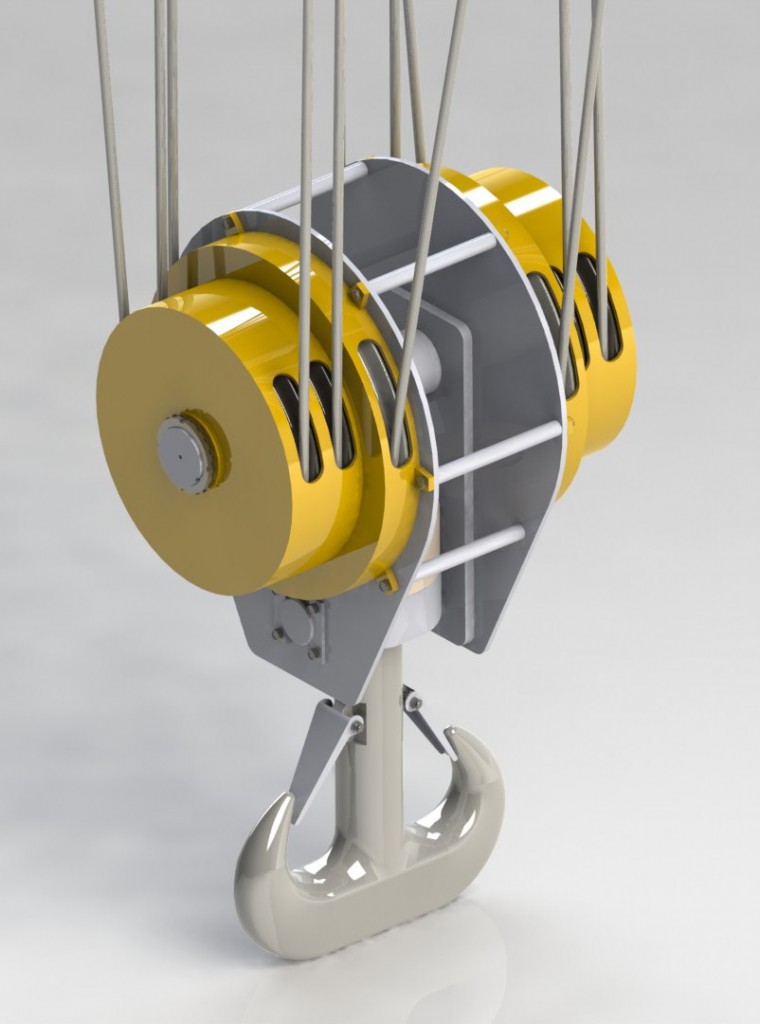

Hook Assembly

Crane Hook Assembly is key part of Cranes and Hoists.Its very important to design and manufacture it very carefully with optimum grade of material.In BHAGAT CRANES, crane hooks production is strictly according to the technology requirements, quality material, proper forging, machining and heat treatment. This is what we do, nothing special. To say something different, the stable quality.

Hook Block Assembly comprising of Hook, Sheave Assembly, Side plates and rope guard. The is supported on thrust bearing and can swivel easily. Hook Block are supplied with Load locking finger and mechanism to stop hook rotation when requested by customer.

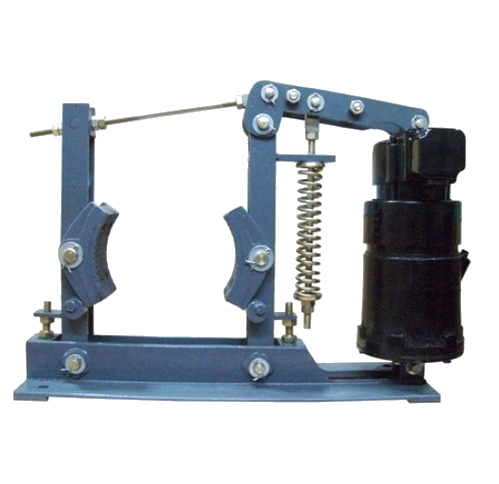

Brake Drums and couplings with brake drums

Brake drums are made from rolled bar or cast steel. The brake drums are fully machined to eliminate vibration. Brake drums are dynamically balanced after machining when required by customer. The drum surface is treated to achieve high hardness for longer life.

Rope Drums

Rope Drums are made from seamless pipe or MS rolled plates. Rope drums are supplied with or without flanges as per customer requirement. Butt welded joints in rope drum shell made from MS plates are tested radio-graphically. Rope drums are thermally stress relieved when made from MS plates. Left hand and right hand grooves are machined on rope drum for proper support to wire rope. Connection between hoist gearbox and rope drum can be made through splined joint, flexible in built geared joint or Barrel coupling/ Malmedie coupling. Rope drums are supported at non drive end in drum pedestal that houses anti-friction ball/ spherical roller bearing.

Hook Assembly

Shrouded Bus Bar (DSL) system are used for the electrification of mobile equipment. Shrouded bus bar is a safe, economical and low maintenance way to solve mobile electrification requirement. Depending on the application there are various options and accessories that can be custom engineered for your conductor bar system. Portions of the system can be pre-assembled at the factory to help ease installation. Conductor bar can be found on overhead crane runways, hoists, trolleys, conveyors, port crane and people movers.Insulated bus bars are available from 60 Amperes to 1250 Amps rating. These are modular in construction and compact in size. Spring loaded current collectors are supplied that ensure positive contact with current transmitting surface. Conductors are available in GI, Aluminium, Copper and Stainless steel material. Bus bars with expansion joint, hospital bay and suitable for curved track are also available.

Other Spare Parts

Other spare parts – Electro Hydraulic Thrustor Brakes, Brake Shoe and Lining, AC and DC Brakes, Brake Hub & Rotor, Brake Coil, Brake Armature, Pin Bush Couplings, Geared Couplings, Slip Ring Motors, Sq Cage Motors, Induction motors, dual speed motors, foot and flange mounted motors, Pendent Push button station.